产品介绍

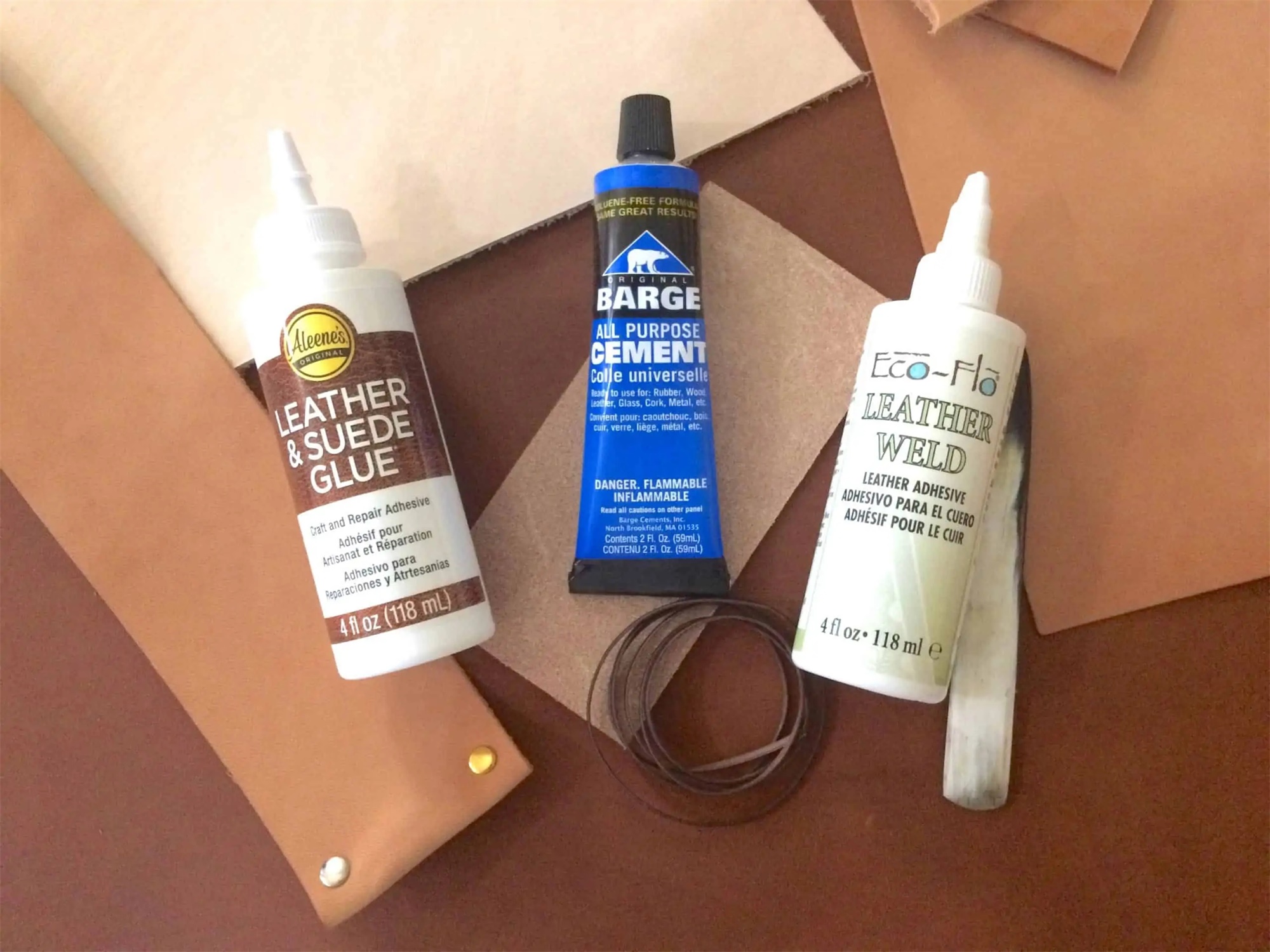

Leather Adhesives

With the continuous development of the leather products market and the increasing focus on quality and environmental performance, the role of adhesives in the leather industry has become increasingly important. VAE emulsions (ethylene-acetate copolymer emulsions) stand out in the field of leather adhesives with their excellent adhesion properties, flexibility, water resistance and environmentally friendly properties. This article will deeply explore the wide application of VAE emulsion in leather product manufacturing and its unique value in improving product quality and environmental performance.

Basic properties of VAE emulsion

VAE emulsion is a water-based emulsion composed of monomers such as ethylene and acetate. It forms a uniform film after coating and exhibits excellent adhesion, flexibility and environmentally friendly properties. This makes VAE emulsion an ideal leather adhesive base.

● 1. Excellent adhesion performance

VAE emulsion can quickly penetrate and form a strong bond after being applied to the leather surface. This excellent adhesion property ensures that the various parts can be firmly adhered together, improving the overall strength of the product. For leather products, such as shoes, bags, etc., adhesion is an important factor in ensuring the durability of the product.

● 2. Flexibility and adaptability

Because VAE emulsion forms a flexible film after curing, it imparts a certain flexibility to the bonded area. This is particularly important for leather products that face constant changes in shape and external forces. It helps slow down damage to bonded areas caused by regular use, bending and deformation, thereby increasing product life and durability.

● 3. Water resistance and durability

In the production of leather products, it is often necessary to face humid environments or frequent use. The film formed by VAE emulsion after curing shows excellent water resistance, ensuring that the product can still maintain excellent adhesive properties under humid conditions. This is especially critical for leather products for outdoor use, such as rain gear, outdoor shoes, etc.

● 4. Low odor and low VOC

As a water-based emulsion, VAE emulsion has the characteristics of low volatile organic compounds (VOC) and avoids the pungent odor that may be produced by traditional organic solvent adhesives. This provides a more comfortable experience for the production of high-quality leather products, especially products that need to come into contact with the skin, such as shoes, gloves, etc.

● 5. Easy to coat and process

The liquid nature of VAE emulsion makes it easy to apply to leather surfaces of different shapes and sizes. This allows manufacturers to more flexibly respond to the production needs of various leather products, improve production efficiency, and reduce production costs.

● 6. Environmental protection characteristics

As society continues to pay attention to environmental protection, VAE emulsion, as a water-based emulsion, does not contain organic solvents, has no volatile organic compound emissions, and complies with modern environmental protection standards. This not only helps reduce the environmental impact of production, but also helps create more environmentally friendly leather products that meet consumer demand for sustainability and environmental protection.

● 7. Good colorability

Since the VAE emulsion itself is milky white and has good transparency, it will not have a significant impact on the color of the leather. This is important for making products such as high-end leather goods and custom footwear that require color consistency.

Application of VAE emulsion in different leather products

● Footwear manufacturing: VAE emulsion can be used for bonding soles and uppers to ensure that footwear products have a strong structure and good appearance.

● Luggage manufacturing: When making leather bags and luggage, VAE emulsion can be used to bond different materials, such as leather, fabric and metal accessories, to ensure the firmness and durability of the product.

● Car interior: Due to the low odor and environmentally friendly properties of VAE emulsion, it is suitable for the manufacture of leather interiors such as car seats and steering wheels, improving the quality of the interior environment in the car.

● Gloves and other leather products: When making gloves, belts and other leather products, VAE emulsion can ensure the bonding strength of different parts and increase the comfort and durability of the product.

As an advanced leather adhesive base, VAE emulsion provides reliable solutions for the production of various leather products through its excellent adhesion performance, flexibility, water resistance and environmental protection properties. Its successful application in multiple application fields reflects its importance and widespread popularity in modern industry. With the improvement of quality and environmental protection requirements, VAE emulsion will play a more important role in the future leather industry and become the first choice adhesive for manufacturing high-quality, environmentally friendly leather products.