AS-103 | VAE Emulsion

Product Introduction

AS-103 | VAE Emulsion

VAE Emulsion

Physical and chemical properties:

Full name: Vinyl acetate-ethylene copolymer emulsion

Common name: VAE Emulsion | EVA Emulsion

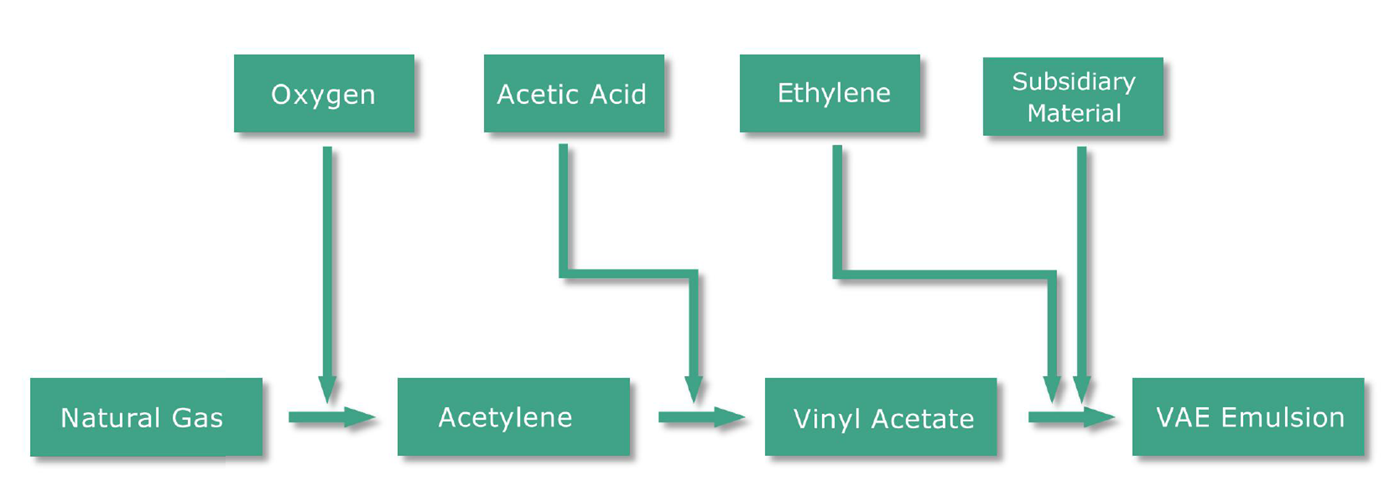

Manufacturing method:

A polymer emulsion made from vinyl acetate and ethylene produced by the natural gas acetylene method as raw materials and other auxiliary materials through an emulsion polymerization process. The main process flow is as follows:

Product Characteristics

Exterior

White or slightly yellow emulsion, no coarse particles, foreign matter and sediment.

Density

1.03-1.08kg/L

Permanent softness

VAE emulsion is embedded with ethylene monomer, which increases the rotational freedom of the polymer chain and has small steric hindrance, making the VAE polymer internally plasticized, without plasticizer migration, and permanently soft.

Good film forming properties

The film-forming temperature of VAE emulsion is lower than room temperature, and it can form a good film. The film is colorless or slightly yellowish and transparent, with a slightly sticky surface. The film has good barrier properties against water droplets.

Good weather resistance

VAE emulsion has good resistance to damage caused by ultraviolet rays in the atmosphere, and the polymer is not prone to brittleness and breakage.

Resistant to weak acid and alkali

VAE emulsion can be mixed with both weak acids and weak bases without causing the VAE emulsion to break.

Broad compatibility

VAE emulsion can be mixed with most pigments and fillers, and can also be water-soluble polymerized with many additives, organic acids, aldehydes, esters, halogenated hydrocarbons, aromatic hydrocarbons, polyols, higher alcohols, ketones and other low molecular substances and polymers. blends with many other polymer emulsions.

Good adhesion

VAE emulsion has good adhesion to wood, paper, fiber, aluminum foil, plastic film, ceramics, cement and other products.

Product Applications

Adhesive base material

Adhesives are the main consumer market for VAE emulsions, accounting for about 40%. It is mainly used as the base material for adhesives such as wood, leather, fabric, paper, cement, concrete, aluminum foil, galvanized steel sheets, etc. It can also be used as the base material for pressure-sensitive adhesives and heat sealants, especially as polyethylene, polypropylene, Base material for difficult-to-bond film adhesives such as polyvinyl chloride and polyester.

Coatings

Latex paint based on VAE emulsion is one of the commonly used paints. VAE latex paint can be used as outdoor insulation, interior and exterior wall coatings, roof waterproof coatings, fire retardant coatings, anti-rust coatings, and floor coatings. The VAE latex paint film has good blistering resistance, aging resistance and is not prone to cracking. It can be coated not only on wood, masonry and concrete, but also on metal, glass, paper and fabric surfaces. It also has a good affinity with paint. , can be painted on each other's surface.

Paper processing

VAE emulsion can be used in paper processing. It is more superior than other emulsions. It is mainly used for paper impregnation, paper coating and pulp addition. It is characterized by being able to polish a variety of papers and increase the dry and wet strength, toughness and gloss of the paper. degree, improve color stability, reduce ink printing consumption, and improve paper quality. As a pulp additive, various types of non-asbestos gaskets can be made. VAE emulsion can also be used in special paper processing, such as napkins, face towels, diapers, sanitary napkins, etc.

Cement modification

Simple cement products have shortcomings such as easy cracking. VAE emulsion has permanent flexibility, good weather resistance, good modification effect on cement, and the price is cheaper than similar products.

Redispersible polymer powder

The redispersible latex powder product is a water-soluble redispersible powder. It is made from VAE emulsion as the main raw material and polyvinyl alcohol as the protective colloid, which is dried and pulverized. Because redispersible latex powder has high bonding ability and unique properties, and is easy to transport and store, their application range is extremely wide.

Non-woven fabric processing

Non-woven fabrics are not woven, and the fibers are arranged randomly. In order to prevent the fibers from shifting and tearing, they need to be glued to increase their strength. There are two methods of gluing: dipping or spraying. The glue concentration is about 10%.

Carpet processing

Carpet adhesives were originally commonly used as styrene-butadiene latex, styrene-acrylic emulsion, etc. After the advent of VAE emulsion, many carpet manufacturers switched to VAE emulsion because its comprehensive properties such as water resistance, heat resistance, and color retention are superior to other emulsions and its price is cheap. Use VAE emulsion as adhesive.

Factory & Warehouse