PVA | 10-99 (L)

Product Introduction

PVA | 10-99 (L)

Polyvinyl Alcohol

Physical properties:

English name: Polyvinyl Alcohol

Common name: PVA

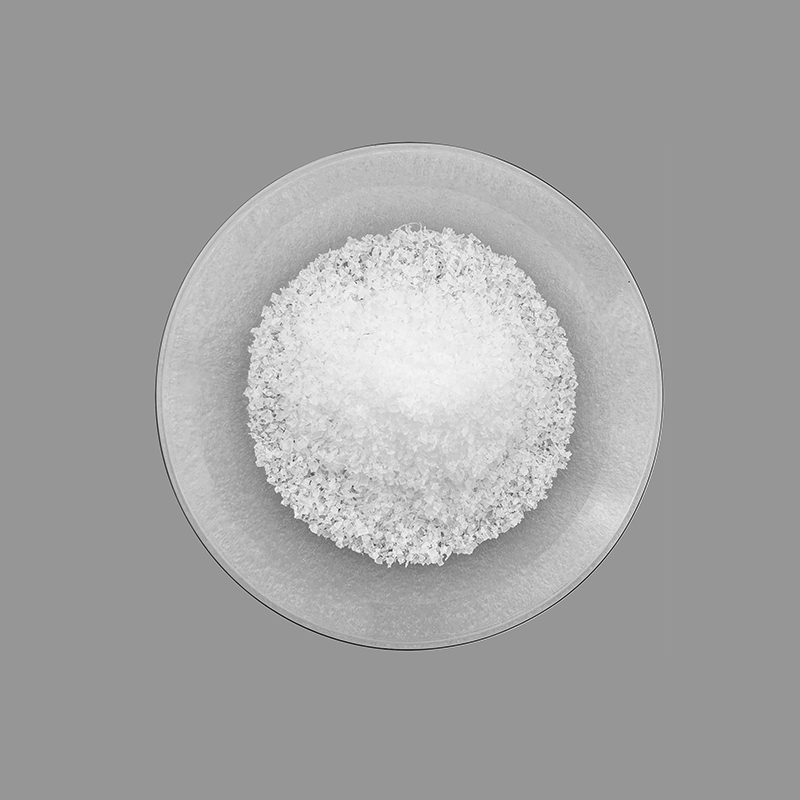

Appearance: The finished PVA product is solid, and its appearance is divided into white flakes, granular, powdery (low-alkali alcoholysis process) or flocculent (high-alkali alcoholysis process).

Specific gravity: 1.19-1.31 g/cm³, sheet PVA filling specific gravity 0.42-0.51 g/cm³, frame PVA filling specific gravity 0.20-0.27 g/cm³.

Chemical properties:

The structural formula of PVA is -[CH2CH(OH)]n-, where n represents the average degree of polymerization. The basic properties of PVA are determined by its average degree of polymerization and alcoholysis. However, there are more than 10 irregular structures in PVA molecules, which also have a great impact on its performance.

(1) Water solubility: PVA molecules contain a large number of radicals and are easily soluble in water. Its solubility increases with the increase of water temperature, it only swells in cold water (low alcoholysis products can slowly dissolve in normal temperature water), and can be completely dissolved in hot water. Its aqueous solution has good film-forming and adhesive properties. .

(2) Thermal stability: PVA series products soften when heated. There is no significant change below 40C. They will gradually color when heated for a long time above 160°C. They decompose above 220°C to produce water, acetic acid, acetaldehyde and crotonaldehyde. wait.

(3) Chemical resistance: PVA series products are almost not affected by weak acids, weak alkali or organic solvents, and have high oil resistance.

(4) Storage stability: PVA series products have good stability and will not become moldy, deteriorate or absorb moisture when stored for a long time in a naturally dry state.

(5) PVA is a high molecular polymer with secondary light groups. The secondary hydroxyl group in the PVA molecular formula has high reactivity and can carry out typical chemical reactions similar to low molecular alcohols, such as esterification, etherification, acetalization, etc., and can also react with many inorganic and organic compounds. It is non-toxic to humans and animals and can be degraded naturally. It is called a green product.

Manufacturing method:

VAC produced by calcium carbide method is used as raw material, methanol is used as solvent, and peroxide is used as initiator. PVA is made through processes such as polymerization and low-alkali alcoholysis. The annual production capacity reaches 200,000 tons, and it can batch produce more than 40 products with different degrees of polymerization and alcoholysis.

Features | Applications

Polyvinyl alcohol PVA is an important chemical raw material used in the manufacture of polyvinyl acetal, gasoline-resistant pipes and vinylon synthetic fibers, fabric treatment agents, emulsifiers, paper coatings, adhesives, glues, etc.

Model | Main Applications |

04-88 (L) 04-99 (L) 05-88 (L) | Pharmaceutical films, external pharmaceutical substrates, water-soluble films, high-count, high-density yarn materials, photosensitive films for offset printing, papermaking, emulsions, etc. |

05-99 (L) 10-92 (L) 14-92 (L) | Pharmaceutical film, external pharmaceutical base material, warp sizing agent, release agent, emulsifier, etc. |

15-99 (L) 17-88 (L) 20-88 (L) | Oil well cementing concrete modifier, soil conditioner, rewetting adhesive, warp slurry, PVA film, PVAC emulsion protective colloid, photosensitive adhesive, PVB, etc. |

17-92 (L) 17-98 (L) 17-95 (L) 17-99 (L) 17-96 (L) 19-99 (L) 17-97 (L) 20-99 (L) | Fabric sizing agent, fabric finishing agent, paper surface sizing agent, paper pigment adhesive, paper adhesive, emulsifier, PVA film, thermosetting resin improver, ferrite binder, dispersant, coating, glue, PVB, PVF, etc. |

26-99 (L) | High viscosity adhesives, high-end coatings, etc. |

17-99F (L) 26-99 (L) | Vinylon, high-strength and high-module PVA fiber, water-soluble fiber, flame retardant, hollow fiber, etc. |

10-99 (L) DS100 DS200 | Dispersants during PVC polymerization, etc. |

Factory | Warehouse